Conventional Mixing vs. EXAKT Milling

A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg Germany concluded that the quality of compounds processed with three roll mills is better than those processed with electric mixing systems. Particle size is smaller. Particle size distribution is narrow. Ointment stability is better. Temperatures do not increase significantly during processing. […]

Tune-up Your Classic 50 Ointment Mill

Prevent Downtime, Improve Performance EXAKT’s preventative maintenance program extends the life of your mill and reduces downtime. EXAKT ointment mills last a long time, and a little preventative maintenance will add even more years of reliable performance. New – FREE shipping! We take the hassle out of shipping your mill. Schedule your tune-up, and we’ll send you […]

What does an ointment mill do?

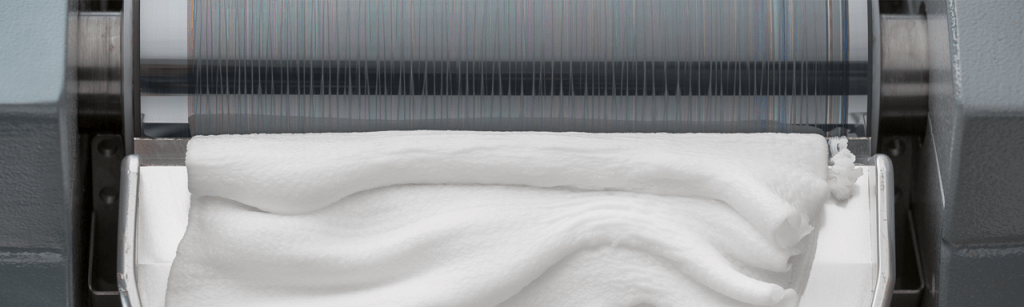

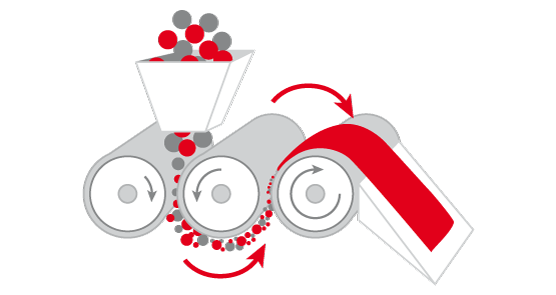

An ointment mill utilizes high shear force to disperse active ingredients, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The product is pulled through the gaps between the rollers. Active ingredients and powder clumps are broken up and […]

Check Out The New 80S Plus!

For maximum fineness, higher throughput. The S-Line series is the entry point for achieving the finest dispersing results. Highlights: Easily monitor speed, temperature, production timer, and power consumption. Adjustable gap range: 5 to 230 µm Variable throughput from as little as 10 ml up to 18 l/h at a 10 μm gap Covers made of blasted […]

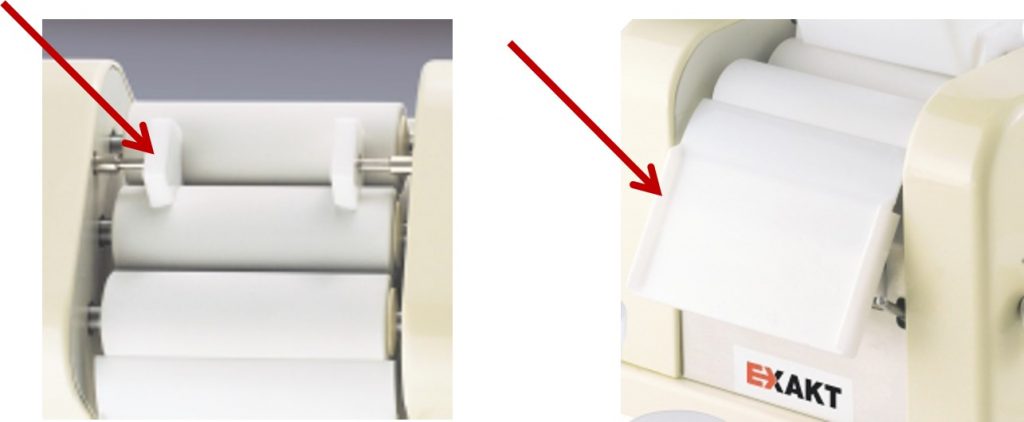

Don’t Forget to Replace the Scraper and Guides

Often times what the operator thinks is a problem with the mill is really just a worn out scraper apron or flow guide. Rule of thumb: If you use the mill daily, replace the scraper and guides every 6 months. Need help? Call or email us today! 800-866-7172 inforx@exaktusa.com

When should you consider an additional mill?

Whether you already own an EXAKT ointment mill or a mill from another manufacturer, the EXAKT 50EC+ is the best choice when considering additional mills. The EXAKT 50EC+ is a modular ointment mill, designed with removable rollers for easy, efficient cleaning. With the purchase of an extra set of rollers, you can increase efficiency in your pharmacy by having […]

The Ointment Mill Process

An ointment mill utilizes high shear force to reduce particle sizes, disperse agglomerates, and homogenize viscous materials. Shear force is created by three horizontally positioned rollers rotating in opposite directions and at different speeds relative to each other. The whole product is pulled through the gap between the rollers, resulting in a precise, controllable, and […]

Introduction to Dispersing with Three Roll Mills

https://www.slideshare.net/EXAKTUSA/dispersion-with-three-roll-mills-introduction?qid=fdeaf89f-2e8a-4bf5-808e-725364c55563&v=&b=&from_search=3

Improve the Performance of Your Ointment Mill.

Your Ointment Mill May Need a Tune-up EXAKT ointment mills rarely require repair, but sometimes a tune-up can help improve the performance of your machine and provide years of worry-free use. For smaller mills, we can turn your mill around the same day it’s received at our shop to minimize downtime. For larger mills, simply […]