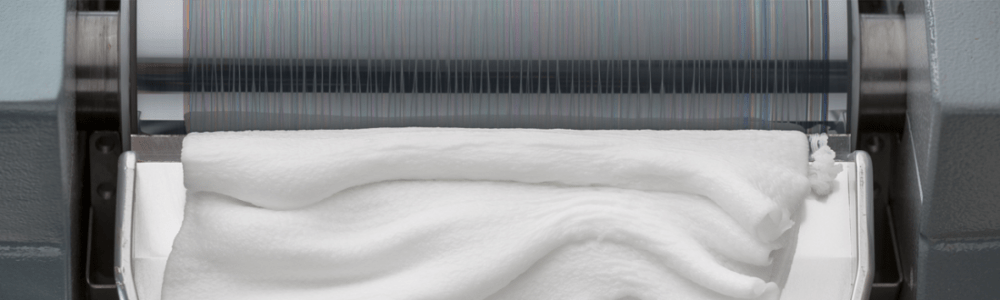

EXAKT’s 50 EC+

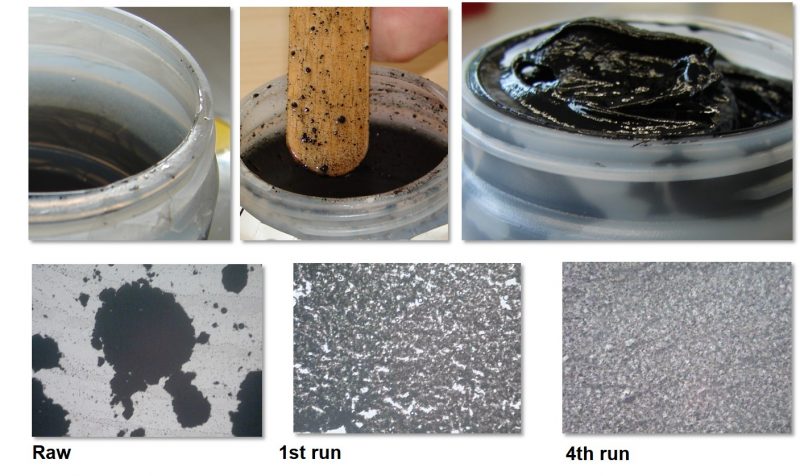

For producing truly elegant preparations of creams, ointments or gels there is no tool more effective or more complete than an ointment mill. And the EXAKT 50 EC+ delivers more control in making that elegant preparation. HIGHLIGHTS › Roller gap to 10 μm › Precise setting of the roller gap, no dry running possible › Up to 5 l/h throughput with a gap width of 10 μm › Continuously adjustable circumferential speed of the rollers › Interchangeable roller set