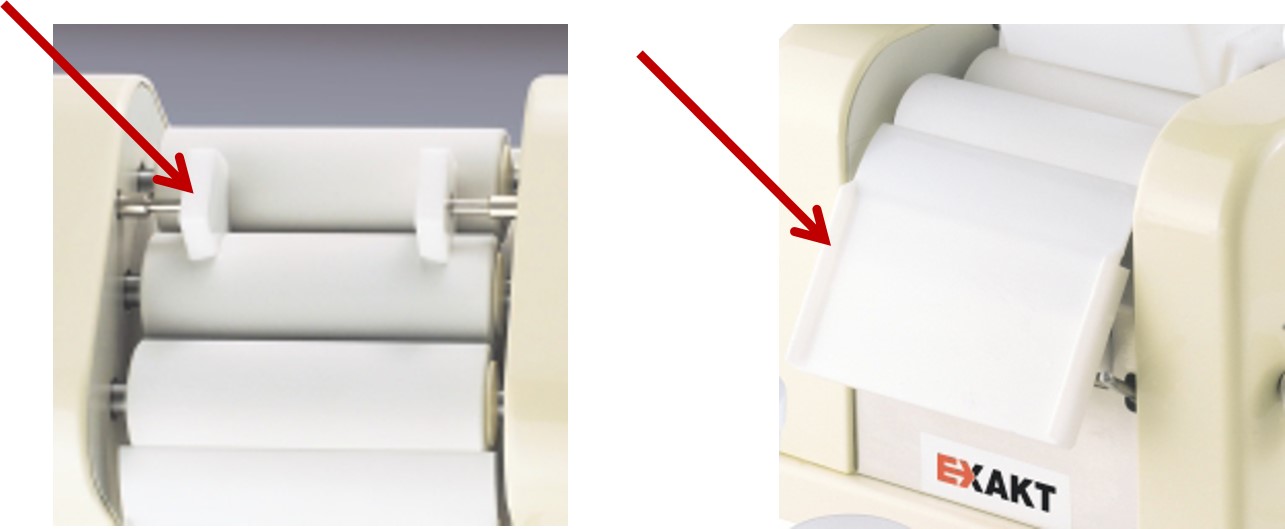

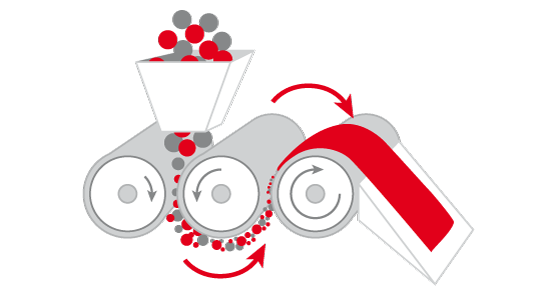

See The New EXAKT 80E Plus

The New EXAKT 80E Plus Demo at Ceramics Expo – Booth # 555 Clevland, Ohio Experience our most advanced mill. It’s smarter, safer, and faster. Come talk to our experts at Booth #555. Tues. May 1st, 10 am – 5 pm Wed. May 2nd, 10 am – 5 pm Thurs. May 3rd, 10 am – 3 pm Can’t make it to the show? Contact us today with your dispersion questions. 1-800-866-7172 info@exaktusa.com