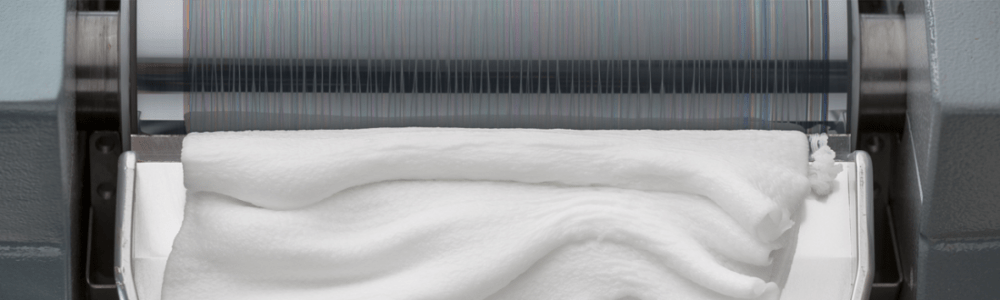

The Water-Cooled Band Keeps You Safe

EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

EXAKT’s 312 Pathology Saw keeps you safe with the water-cooled band. Learn more at PathologySaw.com

Add an extra layer of safety to your EXAKT 50 I three roll mill. Order here. Make a great mill even better Add another layer of safety Attaches fast – no tools needed Save $$ on costly repairs Keep more of your spatulas Designed for EXAKT 50 I use only.

EXAKT three ointment mills deliver results that are consistent and reproducible. A comparative study conducted at the University of Hamburg, Institute of Pharmacy in Hamburg, Germany concluded that the quality of ointments processed with three roll mills is better than those processed with electric mixing systems. The study highlighted the following conclusions: The particle size is smaller. Particle size distribution is narrow. Ointment stability is better. Temperatures do not increase significantly during processing. Ointments are softer consistency with lower flow

EXAKT three roll mills deliver results which are consistent and reproducible. Process materials accurately and dependably, including Nano particles Narrowest particle distribution No separation Processing down to 5 ml, virtually loss free Minimal cleaning losses Durable mills mean low operating costs

Diamond Band – Special characteristics: Distortion-free / corrosion-free stainless steel Single diamond layer, nickel embedded Different band thicknesses and grain sizes Minimized kerf-loss Learn more here.

Prevent Downtime, Improve Performance EXAKT’s preventative maintenance program extends the life of your mill and reduces downtime. EXAKT ointment mills last a long time, and a little preventative maintenance will add even more years of reliable performance. New – FREE shipping! We take the hassle out of shipping your mill. Schedule your tune-up, and we’ll send you a secure box with protective foam inserts, labels, and instructions. For mills 2-5 years Ensure performance Clean and check roller eccentricity for variance Calibrate to

Check out the video below to learn more about cleaning your pathology saw. Cleaning your saw after each use will help improve the safety and performance of your machine. Warning: Do not use disinfectants containing chlorine or aggressive disinfectants such as acetone or nitro thinner. Simply use alcohol-based disinfectant normally found in laboratories. Make sure they are alcohol based.

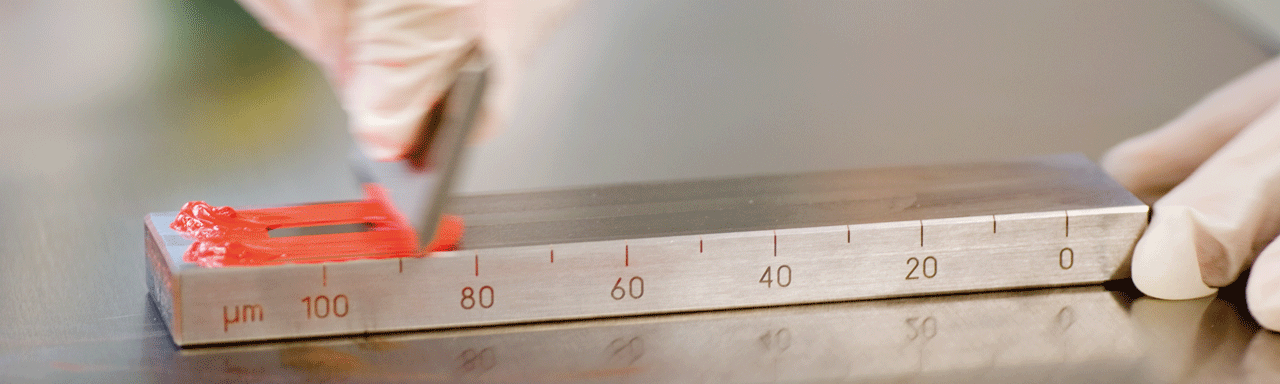

Keep your mill performing as it should. Often times what you think is a problem with the mill is really just a worn-out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering call 800-866-7172. Or email exaktorders@exaktusa.com.

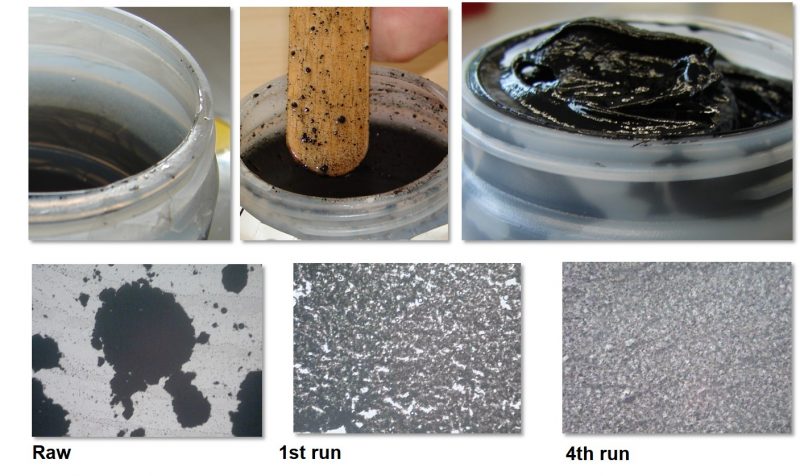

Why should you be using an EXAKT three roll mill for your carbon application? Some of the process advantages include: Disperse the difficult – tangled CNT, especially in viscous pastes such as Epoxy and Silicone. Exfoliate graphite-based materials without destroying the plate-like structure. Control the level of dispersion. EXAKT’s electronic models (80E Plus, and 120E) give the most precise control and repeatability. Whether it’s for research or production, learn more by calling or emailing our three roll mill experts. 800-866-7172 | info@exaktusa.com

Keep your mill performing as it should. Often times what you think is a problem with the mill is really just a worn out scraper and/or guides. If used on a regular basis, EXAKT recommends replacing the scraper and guides every 6 months. For quick ordering call 800-866-7172. Or email exaktorders@exaktusa.com.