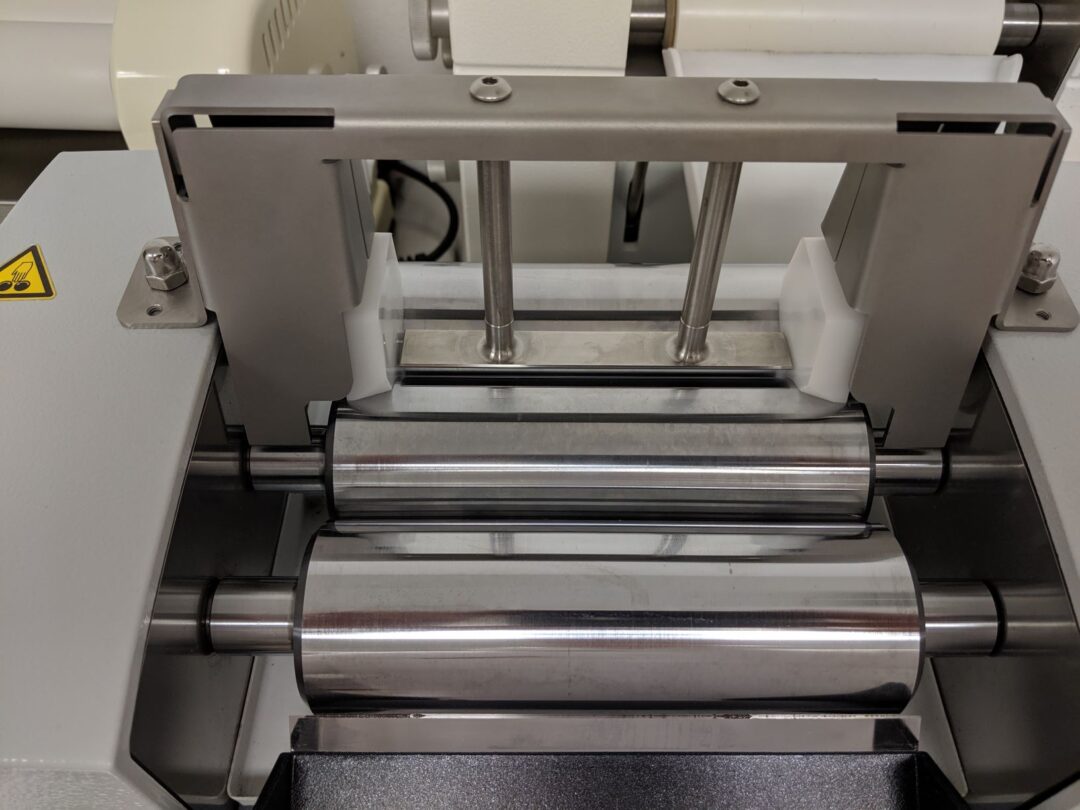

How to Clean Your Pathology Saw

Check out the video below to learn more about cleaning your pathology saw. Cleaning your saw after each use will help improve the safety and performance of your machine. Warning: Do not use disinfectants containing chlorine or aggressive disinfectants such as acetone or nitro thinner. Simply use alcohol-based disinfectant normally found in laboratories. Make sure they are alcohol based.